Visual Executive Project

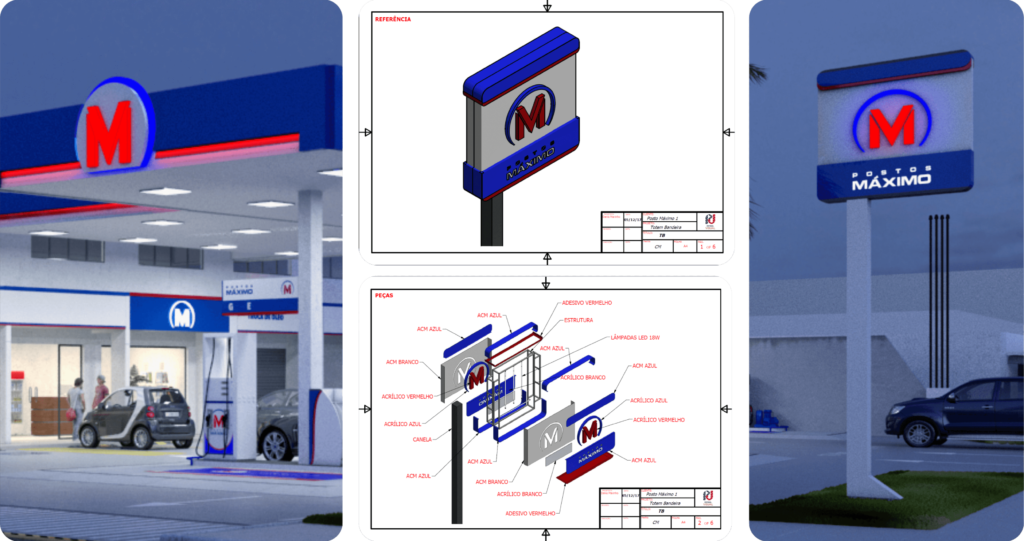

A visual communication executive project is a set of detailed information ranging from the size of each Metalon bar to the position of the LED signs. It is essential to standardize the manufacturing and assembly of elements in all units, which facilitates preventive or corrective maintenance, maintains brand identity and increases customer recognition.

/ STANDARDIZATION

The manufacturing detailing is important to guarantee that the visual communication is safe and resistant, avoiding future problems.

Execution project is created based on a conceptual or descriptive project provided by the client. It is an important stage to ensure the visual communication project is executed accurately and effectively, guaranteeing visual identity project fidelity. It is used as a reference by manufacturers, installers and contractors involved in the implementation of visual communication.

/ CONTENTS

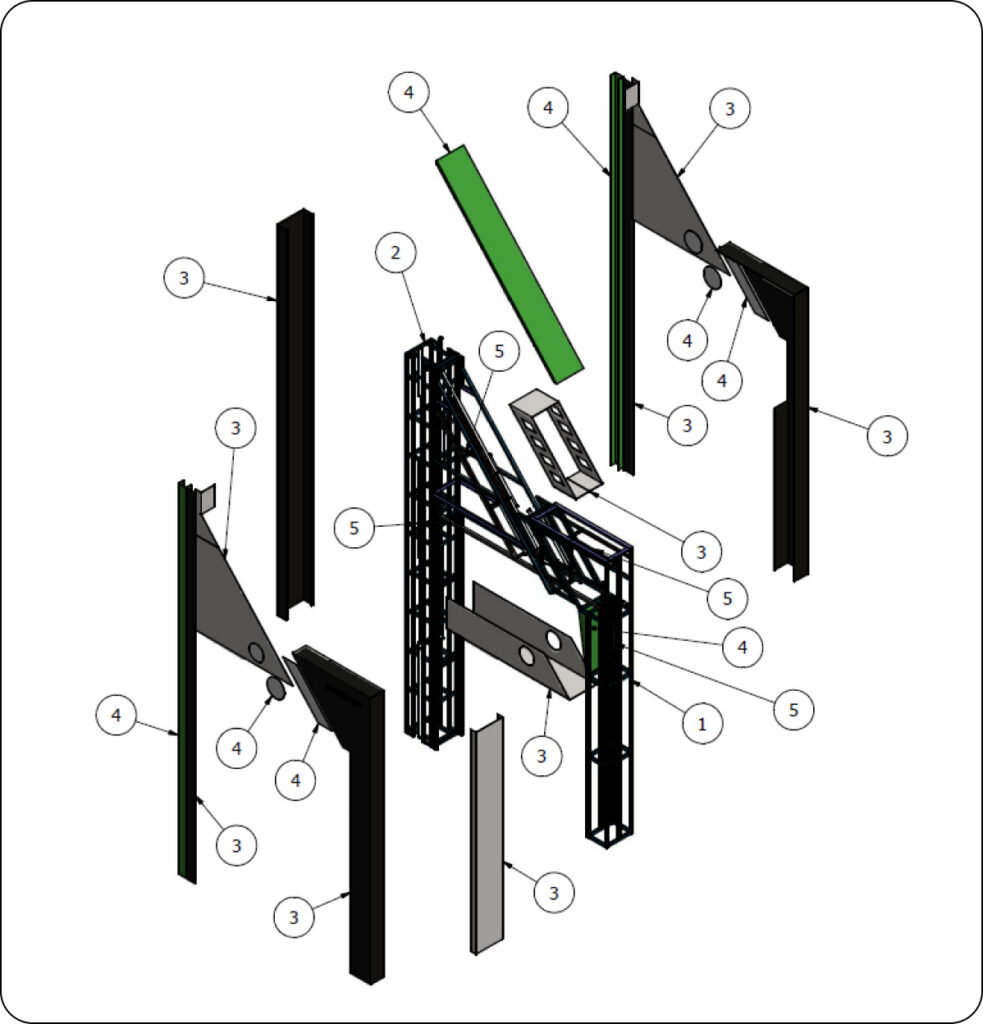

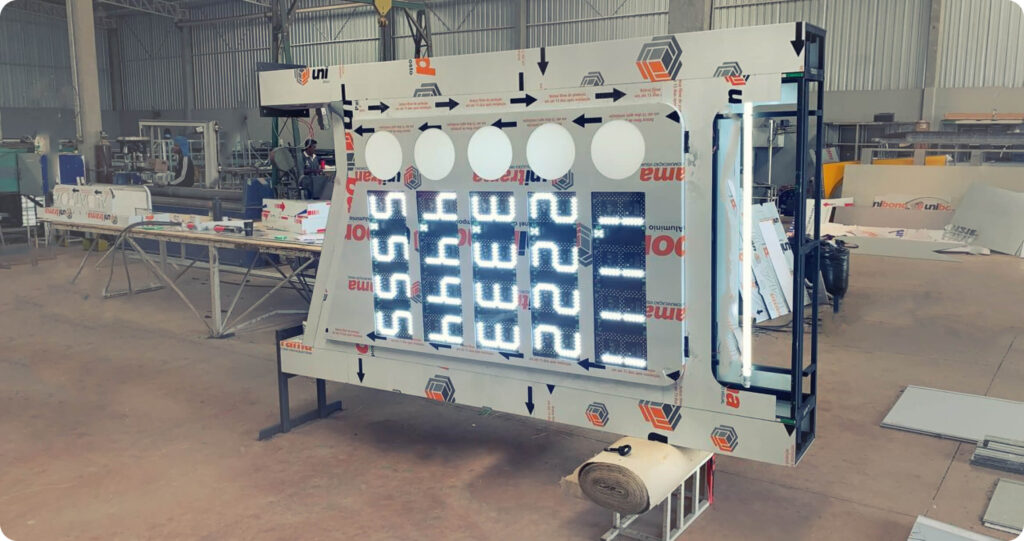

The quantity of Metalon bars and the cutting size of each bar are essential to guarantee the stability and resistance of the metal structure that will support the LED, ACM, acrylic or polycarbonate signs. The position of the lamps is also essential to ensure adequate and efficient illumination of the acrylic or polycarbonate panel surface, allowing the message to be clearly seen. The channel for the passage of electrical cables is important to ensure the organization and safety of the electrical cables that will feed the lamps and other electronic components. The correct position of the UPS, lamps and multimedia LED boards facilitates maintenance.

/ TOO MANY LAYERS

Avoid headaches! Ensure the consistency of your brand’s visual communication across all of your operations.

Our Visual Executive project identifies some groups of information:

Amount of materials;

Elevations; Cuts;

Metallic structure;

Electronic components arrangement;

The document contains specific details regarding the manufacturing of the elements, such as the Totem with LED Boards or Multimedia LED Panels that require special attention to protect the electrical part from rain and to ensure sufficient heat dissipation to avoid damaging the components. Our professionals take into account everything relevant for the safety and durability of each product.

/ WARRANTY

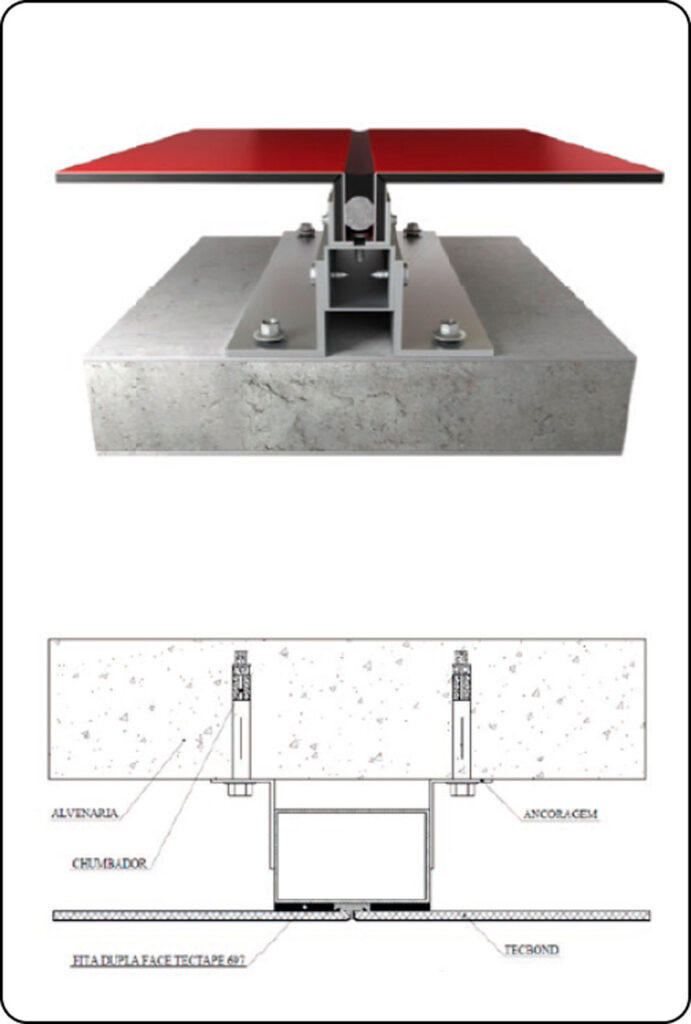

To be sure of the warranty of the materials, the suppliers require a series of details in the manufacturing, installation and maintenance of the material, starting from the different fastening and finishing systems for aluminum composite panels and sheets (ACM), which require knowledge of the ventilation system, the tray system, the dry joint system and the double-sided tape fastening system.

Another necessary care with visual communication elements is to remove the protective liner once the panels are installed to avoid material damage such as drying and staining, which can void the warranty. Finally, the customer should wash the sheets systematically and regularly, always with water and neutral detergent. The metallic colors can suffer color changes on the surface with an alkaline product, while the improper use of solvents and products with acid derivatives can cause damage to the paint (stains), loss of gloss, formation of bubbles, which can also result in the loss of the warranty.